About the factor list

By default a list of factors is provided in the Select factors to vary window and you must select from these. The factor list is composed of:

- A list of the Scenario factors set up in the Excel model. This will typically contain factors such as recipe, temperature, pressure and other operating conditions.

- The factor End Time is also provided so that the ‘batch time’ (i.e. simulation end time) can be varied during the optimization. This is particularly useful when you’d like to know when to stop a process, e.g. to keep an impurity below a certain level or to prevent yield loss from over-reaction of a product.

- The factor Stretch is provided so that imposed profiles can be varied, i.e. stretched or squeezed, during an optimization exercise.

If you want a new factor to be included in the optimization exercise:

- Open your Excel model and add the new factor to the Scenarios sheet

- Open Optimization from Excel and check the model set-up in Simulator

Selecting factors to be varied in the exercise

Using the list of Scenario items in the Select factors to vary window:

- Click on the factor you want to add to the list and then click on the Add button. To select multiple factors you can use shift+move cursor up/down.

- To remove factors from the list, click on the factor you want to be removed and then click on the Remove button.

Setting initial values of factors

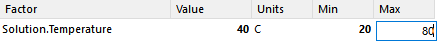

Selected factors can be given initial guesses. By default the initial guess is the value specified in the Scenario chosen to initialize the exercise. This initial guess can be modified before running by typing the new value in the Value column of the Select factors to vary window. During an optimization exercise the factor value is continually updated. The initial guess must lie between the minimum and maximum values indicated in the Min and Max columns (the constraints).

Setting factor constraints (Max and Min values)

You can also set constraints on the factor values so that they remain physically realistic and/or within a known safe operating range.

Both minimum and maximum constraints can be applied to each factor. The default constraints are a minimum of 0.0 and (effectively) no constraint on the maximum. Constraints can be entered in the Min and Max columns and are expressed in the same units as the factor.

Thoughtful setting of constraints can prevent the optimization algorithm giving unrealistic results, e.g. making the process temperature increase indefinitely. Instead, you should think about setting a maximum constraint on temperature equal to, for example, the solvent boiling point.

How the constraints are used during an Optimization run

- If a factor reaches a constraint during a run, the factor is set at the constraint (i.e. the factor is 'fixed') and is no longer varied by the optimization algorithm.

- The Optimization run then continues with the remaining 'free' factors.

- After an optimum is found, Optimization checks to see if freeing any constrained factor improves the optimum, if so, Optimization continues with a new set of free factors.